Instant Coffee and the Environment

- Umeko Motoyoshi

- Sep 8, 2020

- 7 min read

Photo courtesy of Voila Coffee

Instant coffee is perhaps the most divisive way to caffeinate. While many regard instant as unpalatable, half the global coffee market actually prefers it, citing versatility and convenience. And the multi-billion dollar instant coffee sector is growing rapidly, accelerating amidst the COVID-19 pandemic[1] ...not to mention instant’s leading role in the wildly popular dalgona trend.

So what is the environmental impact of all this instant? A tough question, given the complex and often opaque value streams involved in producing most coffee, instant or not. Let’s be clear: any kind of farming has the potential to create negative impacts like deforestation and pollution from fertilizer and pesticides. Because it’s an agricultural commodity shipped across oceans, coffee is inherently problematic to the environment. But coffee also is not a monolith. There is no one way that all coffee is grown. It depends on the region, the type of coffee, the scale of the farm, and the individual practices of that farm. In this article, we’ll look at the production, consumption, and packaging of two distinct products: traditional instant coffee and specialty instant coffee.

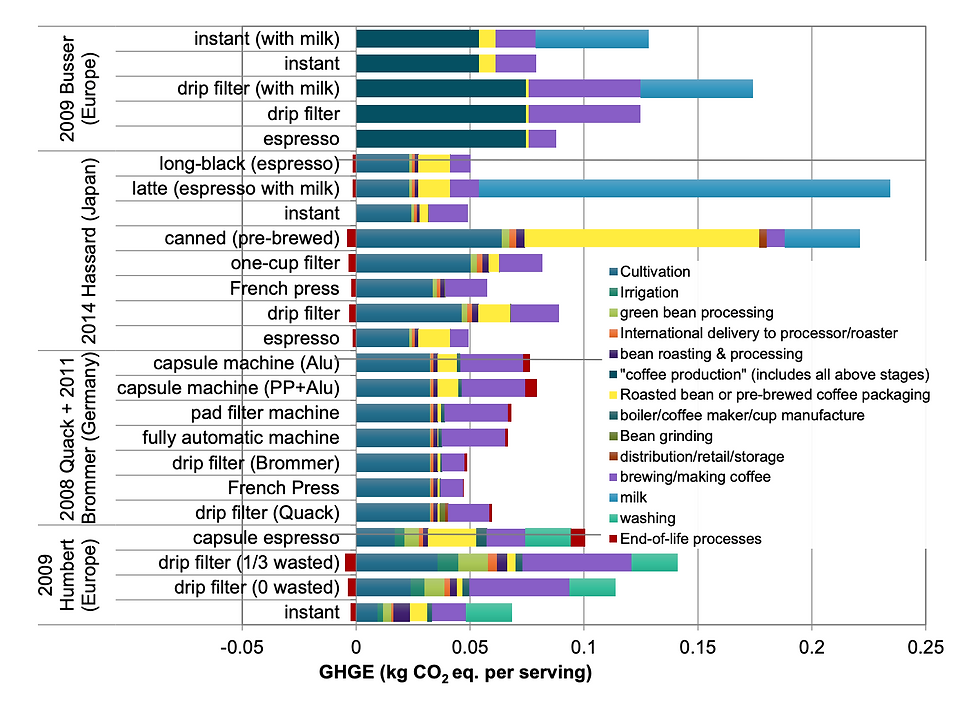

To start, we can distill a guiding viewpoint from existing studies on traditional instant coffee. To measure the carbon footprint of any product, experts conduct what is called a life cycle assessment (LCA). LCAs examine every process in the life of a given product, from manufacturing to end use. Several well-known LCAs have been conducted on instant coffee compared to other brewing methods, all returning similar findings[2]. First, cow’s milk is actually the make-or-break factor in any coffee beverage’s carbon footprint. Due to their milk content, lattes are responsible for more than four times the carbon emissions as instant. Second, out of all the ways we drink coffee, traditional instant has the smallest carbon footprint.

Findings from a 2017 meta-study by the State of Oregon Department of Environmental Quality

Traditional Instant Coffee Production

A quick overview of how traditional instant coffee is made: it starts out as concentrated, liquid brewed coffee. Like a regular cup of coffee, this concentrate is made of two ingredients - water and coffee solids (coffee solids, dissolved from coffee grounds during brewing, are the flavors that make coffee taste like coffee). Concentrated coffee just has more solids and less water. To produce instant coffee, concentrated coffee is dehydrated, usually via a process called spray drying. This leaves behind dry coffee solids, which are then packaged as instant coffee.

You would think that this processing might carry a huge carbon footprint. But it happens at a massive industrial scale, allowing instant coffee brands to become highly efficient. As an example, spent coffee grounds are often used as an energy source for the dehydration process.

Surprisingly, instant coffee’s biggest emissions savings occur on the coffee farm. Why? This isn’t made explicitly clear outside of academic paywalls. I have two theories, based on my three years sourcing manufacturing technology at an instant coffee company. First theory: the carbon emissions associated with cultivating the coffee are lower simply because fewer coffee beans are used to produce it. Traditional instant manufacturing extracts up to 70% of the coffee beans to create the concentrate that’s then dehydrated. By contrast, a regular cup of coffee is brewed with only a 20% extraction of the beans (for more info on coffee extraction, check out my article Measuring Coffee Extraction, and Why it Makes People Mad right here on the Biocaf blog). Second theory: Carbon emissions from instant could also be lower because instant relies on a specific grade and species of green coffee which is cultivated at large scale with extreme efficiency. The flavor of this coffee is more bitter, but the carbon emissions could be lower because of scale and efficiency.

Specialty Instant Coffee Production

Photo by Black & White Roasters

It’s clear across existing studies that traditional instant coffee has the lowest carbon footprint per cup. But in recent years a new category has emerged: specialty instant coffee. And it’s growing fast! Especially during COVID, specialty instant brands are reporting a marked uptick in sales. Nick McPherson, owner of specialty instant brand Juno Coffee, experienced a sales hike so extreme it caused production issues. Kyle Ramage, co-owner of Black & White Roasters, is scaling their instant coffee production due to the increased demand. But what is specialty instant coffee? These up-and-coming brands utilize the classic instant format, with a twist. They swap in a completely different main ingredient: specialty-grade coffee, grown for low bitterness and high natural sweetness rather than pure operational efficiency.

Due to specialty instant coffee’s incredibly tiny slice of the market, there aren’t any environmental studies on its unique value stream. The processes involved differ greatly from those in traditional instant, making it impossible to apply LCA findings between these categories. So, what are the main differences?

Firstly, the farming involved looks totally different. Specialty-grade coffees require more complexity in cultivation and are grown at a smaller scale than the coffees used in traditional instant. Another departure: the brewing process by which coffee concentrate is produced. Those 70% extractions we discussed are efficient, but they also contribute to strong bitterness and other flavors the specialty category avoids. Specialty instant brands use much gentler brewing processes.

The dehydration method is also completely different. Instant coffee giants use industrial-scale spray-drying, while specialty brands typically freeze-dry in small batches - a process favored for its remarkable ability to preserve flavor complexity. The process is not without drawbacks. “Freeze drying consumes quite a bit of energy,” says Kyle of Black & White Roasters. However, spray drying also consumes a lot of energy. And it’s difficult to compare across massive differences in scale.

We lack the data to make per-cup comparisons between the carbon impact of traditional vs. specialty instant. However, per-cup comparisons don’t tell the whole story. In total, the global, multi-billion-dollar instant coffee industry consumes more energy and resources than the handful of independent specialty brands. The sheer scale of farming involved in supplying half the world’s coffee drinkers with instant coffee? No matter how low the carbon emissions per cup, the total overall impact on the environment also includes deforestation, pollution, and destruction of habitat. Specialty instant, as it is currently defined, just doesn’t scale to anywhere near that size. So it’s helpful to consider overall environmental impact as well as per-cup carbon emissions.

Instant Coffee at Home

Photo by Voila Coffee

When we focus on the home use experience, both traditional and specialty instant deliver obvious benefits. The process of grinding and brewing whole beans creates almost half the total emissions involved in regular drip coffee. Instant coffee preparation produces a total of ⅓ the emissions of drip preparation. And compared to the fussy experience of brewing specialty coffee, instant is much more efficient.

“I see massive benefits when it comes to waste,” says Kent Sheridan, founder of specialty instant brand VOILA. “You’re eliminating the need for dial-in and bad cups, and it saves the need for brewing equipment or consumables like filters.” Says MiMo, Production and R&D Lead at Juno Coffee, “Instant guarantees that the brewer will always have the same consistent cup. The consumer doesn’t have to create more waste while brewing.”

Not to mention, when stored properly instant coffee has a shelf life of twenty years. That means no tossing out of coffee beans that have staled beyond drinkability. There’s also shipping to consider. Instant coffee can produce the same number of servings as whole bean at about 20% of the shipping weight and volume. It’s important to note that these potential benefits are most applicable when shipping large wholesale amounts of product.

Packaging

Juno Coffee offers reusable glass jars for larger instant coffee orders

At Juno Coffee, MiMo and Nick implement small changes to continually reduce their environmental impact. Says MiMo, “The little packets are not completely biodegradable because of the foil lining, but that’s why we also have reusable glass jars for bigger orders.” MiMo is also interested in reducing single-serve packaging. “Maybe we can find a way to make instant into something like sugar cubes.”

In the search for more eco-friendly ways to approach coffee, product innovation will inevitably play a key role. Says Kent, “I’d say the most environmentally friendly coffee product would be a biodynamically farmed, natural-processed coffee & cascara concentrate (brewed at a higher concentration vs post extraction concentration) served up in a resealable recycled aluminum can. What do you think, should it be alcoholic too?”

Looking for a sustainable coffee that, well, already exists? Kyle, who is also the 2017 US Barista Champion, suggests coffee grown in Ethiopia. “They have massive systems in place that utilize organic and sustainable agriculture. I would say a naturally processed coffee, as they utilize less water, or at the very least a coffee from Western Ethiopia that utilizes less water in processing, via the ecopulper. Then of course buying it in the largest package possible, as that has less waste than the smaller retail bags, and consuming it locally, avoiding the shipping across the country/world. Then upcycling or recycling the packaging. That would be the formula.” The takeaway here? We must keep pushing to make all coffee more eco-friendly. But compared to other brew methods, instant is just fine. So relax and enjoy! Whether it’s a classic cup of Bustelo or a fruity specialty Kenyan, the instant coffee category has more options than ever. Just go easy on the milk.

Resources

[1] *From Jim Watson’s Re:Co Symposium presentation in the event section titled “State & Future of Specialty Coffee Industry”. Jim Watson is a Senior Analyst in Rabobank’s Research group covering the beverages sector.

About the Author

Umeko Motoyoshi is an award-winning coffee writer and educator. A licensed Q-Grader with fourteen years of experience, they founded coffee sustainability platform @wastingcoffee and authored the book Not Wasting Coffee. Umeko is also founder of Umeshiso.com, an online coffee supply shop specializing in rainbow cupping spoons. Umeko’s mission is to make coffee accessible, empowering, and welcoming for people of all backgrounds and identities.

Comments